The Indian oil & gas industry has a history of more than 100 years, starting in Assam where the first oil deposits were discovered in 1889, and the first gas fields were discovered in the 1960s. Fast forward to the present day, India is the third-largest energy consumer in the world and the government thinks that a gas-based economy is crucial for Atmanirbhar Bharat.

This amount of growth means a higher requirement for constant vigilance at every step of the Indian oil & gas industry process cycle to increase output and reduce spillage, accidents, and fuel theft. Time and efficiency become crucial to the outcome.

Drones are shaking up the Indian oil & gas industry for all the right reasons. Here, we will see how this 130+ year-old industry is gearing for the shift.

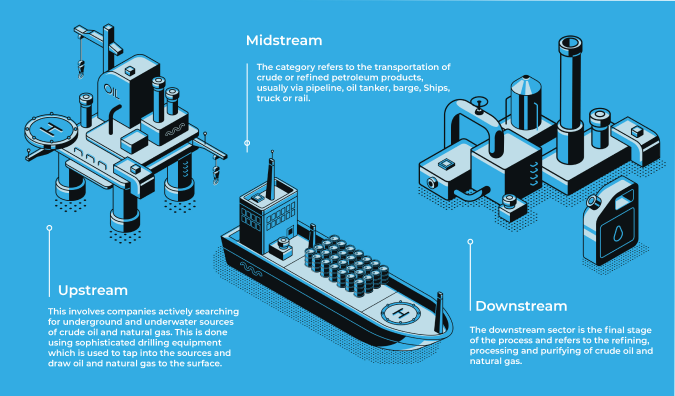

The oil & gas industry is broadly divided into three sectors - Upstream, Midstream, and Downstream. Upstream is the exploration, production, and extraction of crude oil and gas that will then be transported to refineries (midstream) and made ready for various industrial and residential supplies (downstream).

Broadly, the performance of the oil & gas industry is dependent on the following factors:

Now, these factors can pose major challenges and demand high investment in terms of:

Traditionally, all the above steps have been carried out manually. A large amount of manpower and time are invested by the Indian oil and gas industry to ensure minimum loss and sudden shutdowns. Nevertheless, three major concerns remain constant with the manual inspection at every stage:

At each stage, drones hold the capacity to provide live awareness for immediate action.

This process includes the identification of potential geographical sites, survey mapping, drilling and exploration, and production of crude oil and gas. Drones hold the capacity to turn this, otherwise time-consuming, manual process, into an efficient and accurate one in the following manner:

So, all these cuts down the need for onsite human intervention and reduces life risk or chances of human error. Moreover, these checks and surveys can be completed without the need to shut down operations, saving major costs for the companies.

Midstream essentially is the phase where crude oil & gas procured upstream is transferred through pipelines, barges, or oil tankers for the downstream process of refining and storage. Often, challenges come up in the form of long pipelines that may exist over the ground or underwater levels, transport challenges, or excess storage, that require safe storage during treatment and for later transportation as per need. Here, drones can help in the following manner:

Standing at the end of the cycle, downstream is the bridge between oil & gas companies and the end consumer (B2B, B2C & B2G). It is at this stage that procured crude oil & raw natural gas are refined to create required end products like petrol, jet fuel, heating oil, natural gas, LPG, and other petrochemicals.

As downstream is closest to the supply chain, a large amount of manpower and other resources are spent on making sure that the end product is made in time for delivery and in an environment-friendly manner. Industrial residues also need to be discarded properly so that it does not become hazardous for anyone. Here drones can help in the following manner:

Generally, the key types of drones for oil and gas include multi-rotor, single rotor, hybrid & nano and fixed-wing.

Now, it is almost a year that we are dealing with the Covid-19 pandemic. In this age of social distancing and ‘touch me not’ phase, India’s major energy companies are increasingly coming up with innovative solutions to keep the virus at bay and their crucial operations running incessantly. Bharat Petroleum, for example, started leveraging drone technology to record their workers’ behavior to ensure they abide by social-distancing rules.

The Indian Aviation Ministry has allowed Indian Oil, the leading oil marketing company to use drones for aerial surveillance of its pipeline. According to a senior official, this move is expected to arrest oil theft worth several crores in India, and also avoid the safety risk. This move also opens up a plethora of opportunities for surveillance drones in the oil and natural gas sector in the world’s third-largest energy consumer.

Any innovation has its own pros and cons; the increasing use of drones comes with inherent risks as well. Drone technology is here to stay and though drones aim for perfection, they are not flawless. While it is good to acknowledge the benefits that they offer, it is also a good idea to be aware of the risk associated with the technology, especially in the oil and gas sector. This will help operators and companies to take an informed decision.

Some potential risk factors are:

Companies can leverage this technology to the fullest by adhering to rules mandated by the Directorate General of Civil Aviation (DGCA). The Indian government is stepping up regulations in the drone space owing to the risks that come with it. A welcome step is a mandatory insurance that would give a much needed cover to the oil and gas industry where safety is paramount.

According to a recent report, the Government of India is planning to spend around Rs 7.5 lakh crore in creating oil and gas infrastructure over the next five years and the nation is also aiming to reduce the dependency on energy imports. Side by side, the government has also made drone usage safer by opening registrations for drones and drone owners. This will give the government a complete database of drone operators in the country, and help monitor their usage. Currently, any drone operating without a valid Owner Acknowledgement Number (OAN) and Drone Acknowledgement Number (DAN) is considered illegal. Moreover, with the advancements of Artificial Intelligence, we may be looking at drones that would operate with minimum human intervention in the future. Hence, it is safe to say, that a new era is unfolding gradually in front of us and it is up to us to usher in the new beginning.